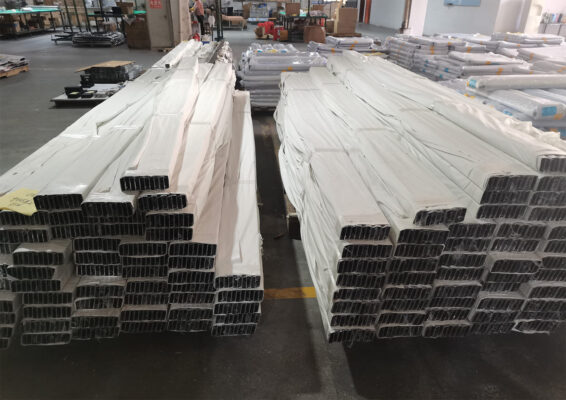

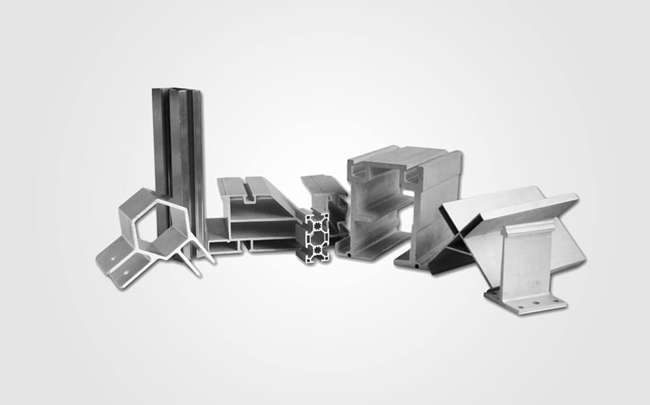

Aluminum Extrusions

- 100,000 Ton Annually Production Capability

- 8Hours fast response by Wellste support team

- ISO 9001-2008 and ISO 14001-2004 Authorized

- 1 xxx,2xxx,3xxx,5xxx, 6xxx, 7xxx series all can be made

Your Premier Aluminium Extrusions Manufacturer

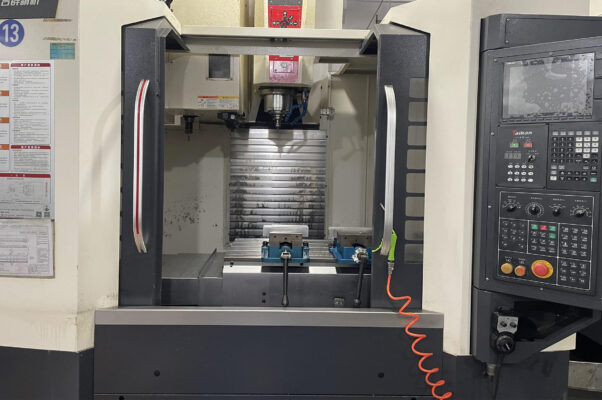

SGS & ISO Audited Aluminum Extrusion

Wellste, a professional aluminum extrusion supplier in China, has been approved by SGS, and obtain ISO quality system certification, ISO environmental management system certification.

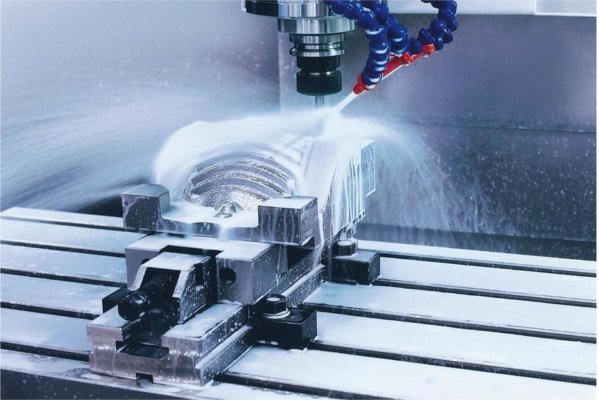

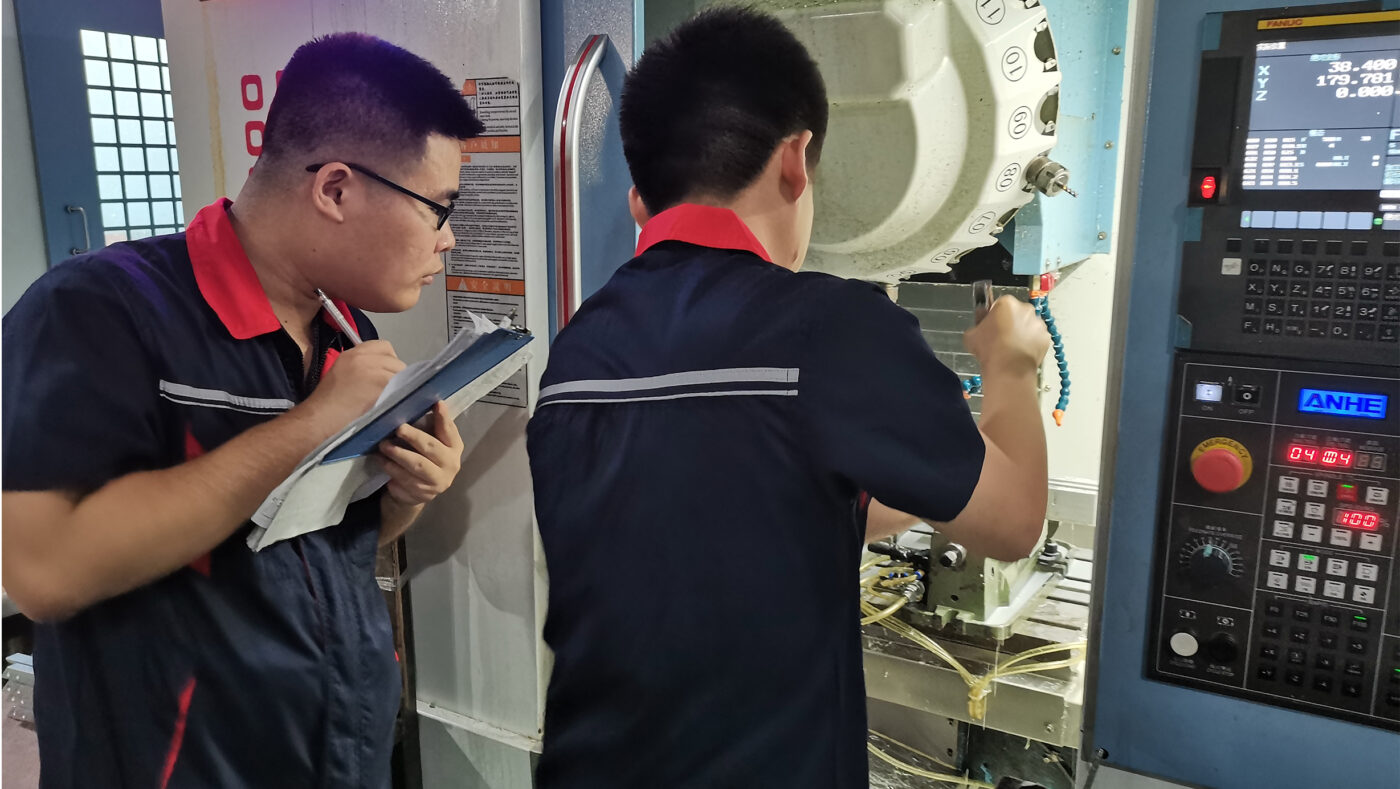

0% Quality Complaint

Wellste has advanced in-house quality testing lab, 48+ QC inspection team, 100% inspected before shipment, which will guarantee the product quality and eliminate your concerns.

Manufacture Test Certificate

We will issue testing certificate each order before shipment. Make sure to meet chemical composition standard and achieve mechanical performance standard.

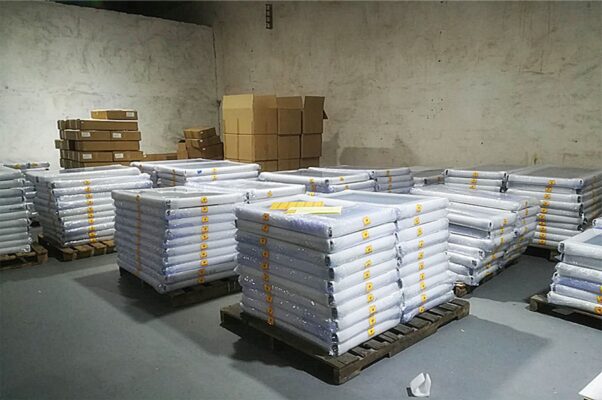

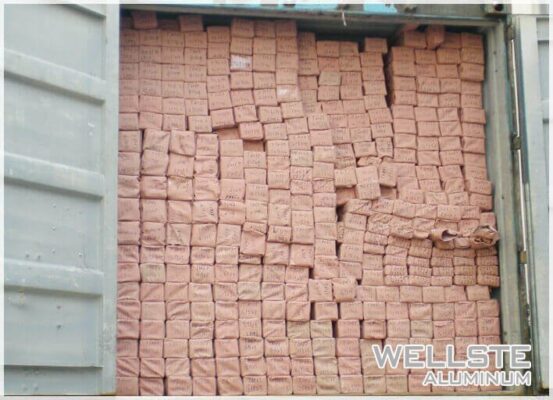

Fast Delivery

Wellste keeps stable delivery time 25 days or less. We own 35 extrusion presses that ensure your delivery date. Even in peak season, we can catch the delivery time. There will be no any delay.

Aluminum Round tube

Aluminum Angle

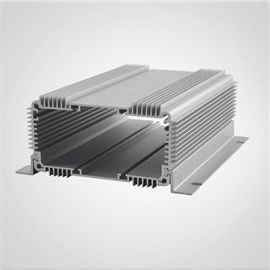

Extruded Aluminum Enclosure

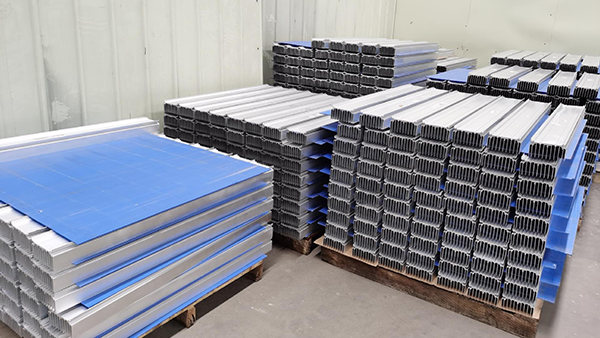

Extruded Heat Sinks

Window & Door Profiles

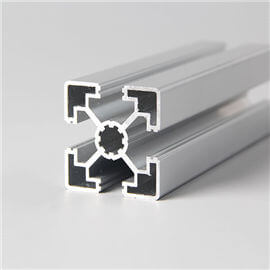

T slotted Aluminum

Solar Panel Frame

Extruded Car Roof Rack