Aluminum Radiator Shells Offer Numerous Benefits When Incorporated Into Industrial Lithium Battery Products. Here Are Key Advantages of Using Aluminum Radiator Shells in Such Applications:

1. Superior Thermal Management

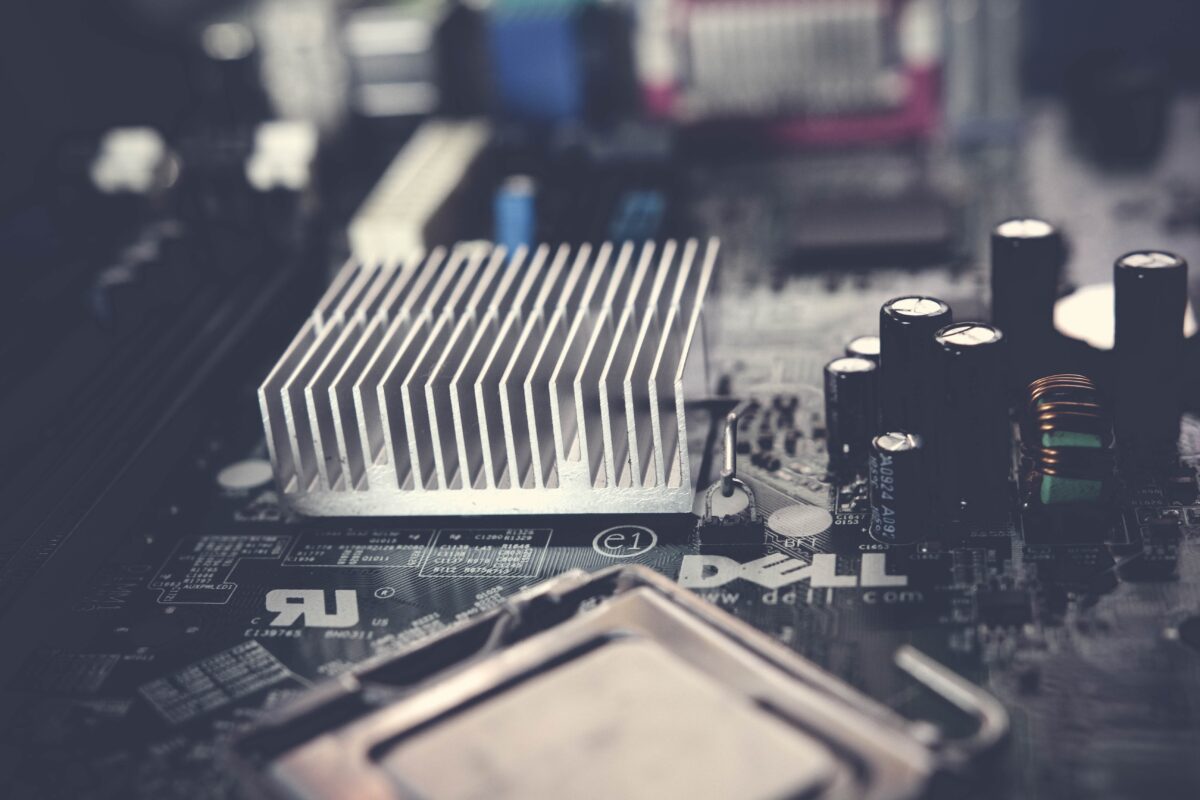

Industrial lithium batteries generate significant heat during operation, which impacts performance and lifespan. Aluminum radiator shells excel in heat dissipation due to the high thermal conductivity of aluminum. They efficiently transfer heat away from battery cells, maintaining optimal temperatures and prolonging battery life. Effective thermal management reduces thermal runaway risks and enhances safety.

2. Lightweight and Compact Design

Aluminum is renowned for its lightweight properties. Using aluminum alloy radiator shells ensures manageable overall weight for battery systems—critical for portable devices or electric vehicles. The compact design enables efficient space utilization, supporting higher energy density.

3. Corrosion Resistance

Aluminum exhibits excellent corrosion resistance, crucial in industrial environments where batteries face moisture or chemicals. Aluminum alloy shells reduce corrosion risks, ensuring long-term reliability and durability.

4. CNC Processing Compatibility

Aluminum is ideal for CNC machining, enabling precise, intricate radiator shell designs. CNC processing allows complex fin patterns, optimized geometries, and tight tolerances, improving heat dissipation and overall performance.

5. Electrical Conductivity

Aluminum’s high electrical conductivity facilitates efficient connections and minimizes resistance in battery systems. This ensures better current distribution, reduced power loss, and enhanced electrical performance.

6. Environmental Sustainability

Aluminum is highly recyclable, aligning with sustainability goals. Recycling aluminum reduces energy use and emissions compared to primary production. Choosing aluminum alloy shells supports eco-friendly practices and a circular economy.

Summary

Incorporating aluminum radiator shells into industrial lithium battery products delivers advantages in thermal management, lightweight design, corrosion resistance, CNC machining compatibility, electrical conductivity, and sustainability. These benefits optimize battery performance, lifespan, and reliability, making aluminum alloy shells a practical innovation for industrial applications.