Introduction

Heat management is a critical aspect of electronic device design, ensuring optimal performance and preventing overheating issues. In this article, we will delve into the world of aluminium heat sink solutions and explore how they play a vital role in achieving cool efficiency.

Understanding Heat Sink Basics

At its core, a heat sink is a passive cooling device used to dissipate heat generated by electronic components. By utilizing the principles of thermal conduction and convection, heat sinks effectively transfer heat away from the source and into the surrounding environment. They consist of a thermally conductive material, usually aluminium, which aids in the efficient dissipation of heat.

Advantages of Aluminium Heat Sinks

Aluminium heat sinks offer several advantages that make them the preferred choice for many cooling applications. Firstly, aluminium is a lightweight material, which allows for easy integration and does not add unnecessary weight to the electronic device. Secondly, aluminium possesses high thermal conductivity, meaning it can rapidly transfer heat away from the heat source, ensuring efficient cooling. Lastly, aluminium heat sinks are known for their corrosion resistance and durability, ensuring long-term reliability in harsh operating conditions.

Design Considerations for Aluminium Heat Sinks

To achieve optimal cooling performance, several design considerations must be taken into account. The size and surface area of the heat sink play a crucial role in heat dissipation. Larger surface areas enable better heat transfer, but the size must be balanced with space limitations and airflow restrictions. Fin design is another crucial factor, as it affects the surface area available for heat dissipation and the airflow through the heat sink. Additionally, selecting the appropriate thermal interface materials, such as thermal paste or pads, ensures efficient thermal coupling between the heat sink and the component.

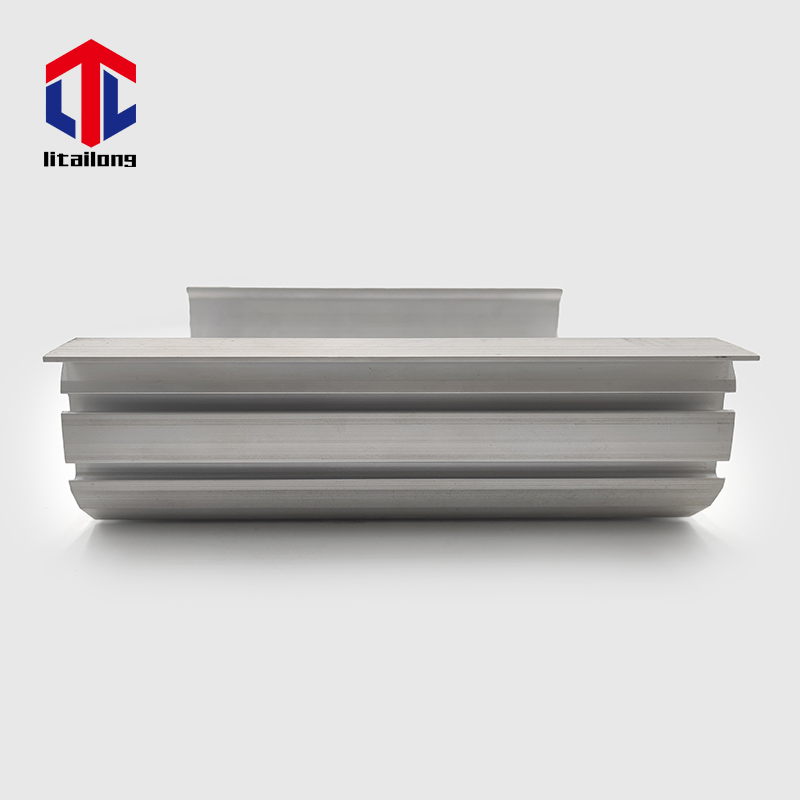

Manufacturing Processes for Aluminium Heat Sinks

The most common manufacturing process for aluminium heat sinks is extrusion. Extrusion allows for the creation of complex heat sink designs with excellent precision and cost-effectiveness. Another technique employed is CNC machining, which enables the production of intricate and custom heat sink designs that cater to specific application requirements. Depending on the complexity and volume needed, other manufacturing methods, such as die casting or forging, may be utilized.

Choosing the Right Aluminium Heat Sink for Your Application

When selecting an aluminium heat sink, several factors must be considered. These include the power dissipation of the component, the ambient temperature in which the device operates, and the thermal resistance required to achieve the desired cooling efficiency. Additionally, customization options such as shape, size, and fin density should be evaluated to ensure the heat sink meets the specific requirements of the application. Through case studies, we will explore how different applications demand unique heat sink solutions.

Installation and Maintenance of Aluminium Heat Sinks

Proper installation techniques are crucial to ensure optimal heat transfer from the component to the heat sink. Attention should be given to using appropriate thermal interface materials and applying them correctly. Regular cleaning and maintenance practices are also essential to keep the heat sink operating at its full potential. This includes removing dust and debris that can hinder airflow and conducting periodic inspections to identify any performance issues.

Innovations and Future Trends in Aluminium Heat Sink Technology

Advancements in heat sink technology continue to push the boundaries of cooling efficiency. Integration of heat pipes and vapor chambers within heat sinks has become increasingly prevalent, providing enhanced heat transfer capabilities. Surface treatments and coatings are also evolving to improve heat dissipation properties, offering better performance and longevity. Furthermore, liquid cooling systems are gaining traction, especially in high-performance applications, where their superior cooling capabilities provide an edge.

Real-World Applications of Aluminium Heat Sink Solutions

Aluminium heat sinks find extensive use in various industries. In the electronics industry, they are vital in cooling CPUs, GPUs, and power electronics, enabling optimal performance and reliability. The automotive sector relies on heat sink solutions to manage heat in electric vehicles, as well as in thermal management systems for internal combustion engines. Industrial applications, such as LED lighting, solar panels, and power amplifiers, also benefit from efficient heat sink solutions to maintain stable operation and maximize lifespan.