Aluminum Heatsink Enclosures play a crucial role in unlocking the performance potential of electronics, especially in applications where heat dissipation is a critical factor. Here are key insights into the importance of aluminum heatsink enclosures:

1. Efficient Heat Dissipation

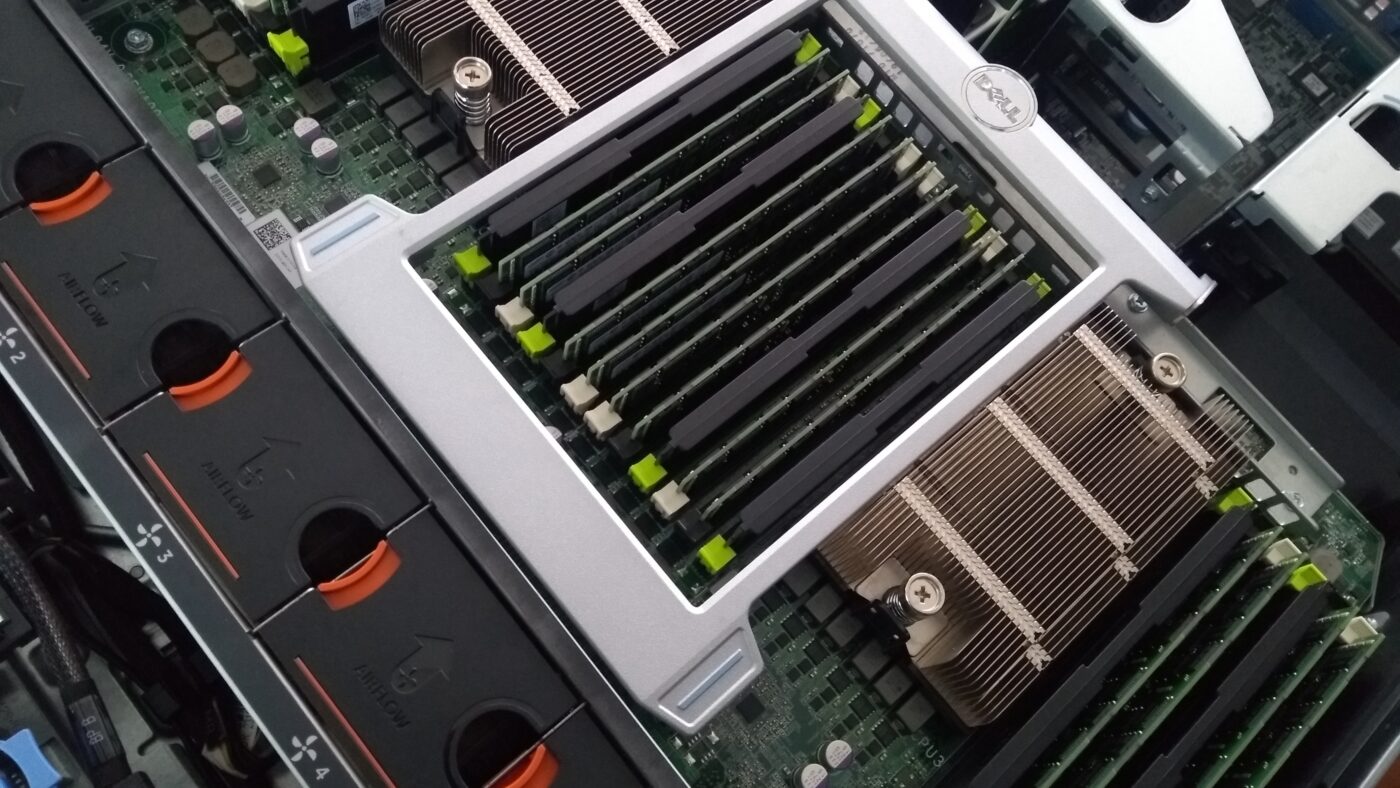

Heat is a natural byproduct of electronic devices and can degrade performance or cause permanent damage. Aluminum heatsink enclosures efficiently dissipate heat from components like processors or power amplifiers. The high thermal conductivity of aluminum enables effective heat transfer to the environment, ensuring optimal operating temperatures.

2. Enhanced Thermal Management

Aluminum heatsink enclosures improve thermal management through intricate fin designs or heat pipes that maximize surface area for heat dissipation. This design enhances airflow and convection, lowering temperatures and boosting component reliability.

3. Lightweight and Durable

Aluminum is a lightweight yet robust material, ideal for enclosures. Its low density minimizes added weight in electronic systems, while its corrosion resistance ensures longevity in harsh environments.

4. Compatibility with CNC Processing Capabilities

Aluminum is highly compatible with CNC (Computer Numerical Control) machining, enabling precise manufacturing of complex enclosures. CNC processing capabilities allow intricate fin patterns, customized designs, and tight tolerances for optimal heat dissipation.

5. Design Flexibility

Aluminum heatsink enclosures offer design flexibility, allowing customization of shapes, sizes, and fin configurations to match thermal requirements. This ensures cooling efficiency and performance enhancement for diverse electronics.

6. EMI Shielding

Aluminum enclosures provide electromagnetic interference (EMI) shielding, leveraging the metal’s conductivity to redirect and absorb electromagnetic waves. This minimizes EMI impact on nearby devices, improving system reliability.

Summary

Aluminum heatsink enclosures are vital for electronics performance, combining efficient heat dissipation, thermal management, CNC processing capabilities, and EMI shielding. Their lightweight yet durable design, coupled with aluminum’s versatility, ensures enhanced reliability and innovation in electronic device optimization.